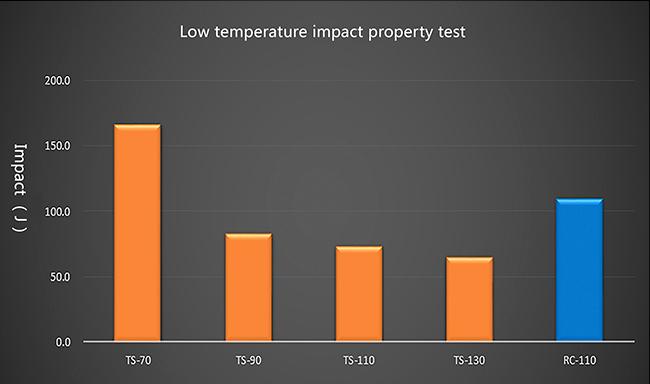

Through advanced heat treatment technology, the microstructure of the coiled tubing is completely improved. The microstructure and mechanical properties of the coiled tubing base metal, oblique welds, and longitudinal seam welds are significantly improved, resulting in a high strength, uniform and stable performance high-quality ReliaCoil products.

| Grade | Yield/min |

Tensile/min |

Hardness/max |

||

|---|---|---|---|---|---|

| RC-110 | psi | MPa | psi | MPa | HRC |

| 110,000 | 758 | 118,000 | 814 | 33 | |