On January 12, Jason Energy Technologies Co., Ltd. (JASON) successfully produced the first 3,400 m corrosion-resistant alloy TS-80CRT (18Cr) ultra-large diameter coiled tubing. It marks that JASON has made the breakthrough in the field of corrosion-resistant alloy coiled tubing production, setting a new world record for corrosion-resistant alloy coiled tubing diameter and leading coiled tubing industry in the world.

Corrosion-resistant alloy TS-80CRT (18Cr) coiled tubing is a high-performance CT product independently developed by JASON. After several rounds of tests, it shows excellent corrosion resistance in high H2S and high CO2 operating environments, and its fatigue life is over 3 times that of the conventional coiled tubing.

In the process of research and development, JASON research team overcame one technical problem after another, and accumulated a large amount of test data on the mechanical properties, welding performance and fatigue life of ultra-large diameter corrosion-resistant alloy coiled tubing.

Corrosion–resistant Alloy TS-80CRT (18Cr) Coiled Tubing specifications

Chemical Composition

Chemical Composition of Corrosion-resistant Alloy 18Cr (mass fraction %)

| Component | C | Si | Mn | P | S | Cr |

|---|---|---|---|---|---|---|

| Mass fraction | ≤0.10 | ≤1.00 | 4.0-7.0 | ≤0.050 | ≤0.005 | 17.5-19.5 |

Mechanical Property

Tensile Strength Rm |

Specify Plastic Extension Strength Rp0.2 |

Percentage Elongation after Fracture A |

|---|---|---|

≥700 |

≥385 |

≥45 |

Corrosion Test

Standard Sulphide Stress Corrosion Test

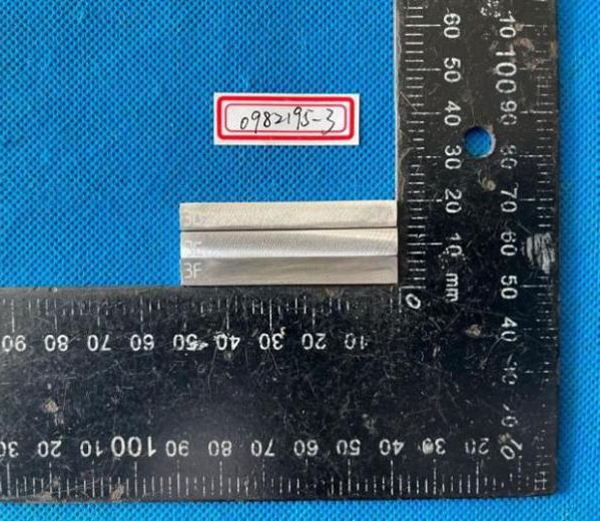

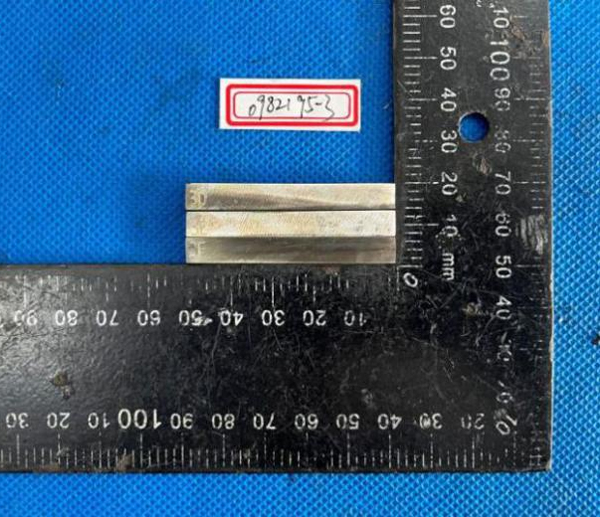

According to NACE TM0177 corrosion test standard, the anti-sulfide stress corrosion test of corrosion resistant alloy TS-80CRT(18Cr) coiled tubing was carried out by using C-ring method. After 720h test, no cracks were found in base material and welding seam.

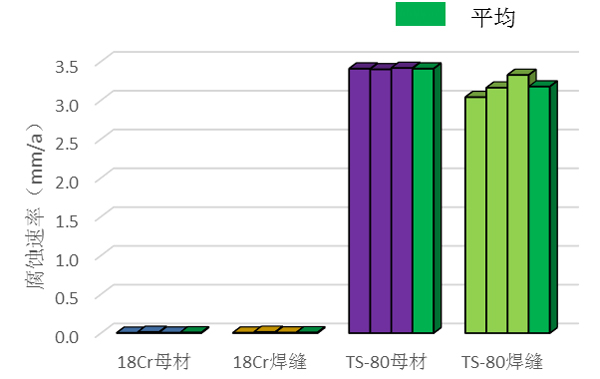

CO2 Corrosion Test

The corrosion test of saturated CO2 solution was carried out according to ASTM G111 standard, and the corrosion resistance ofCO2 is more than 1,000 times that of TS-80 coiled tubing.