Corrosion damage carbon dioxide

Carbon dioxide corrosion is a kind of electrochemical corrosion on metal which is caused by Hydrogen ion(H+), bicarbonate ion(HCO3-) and carbonate ion(CO32-)generated from a certain percentage of carbon dioxide dissolved in production water in the oil and gas wells, especially high concentration of carbon dioxide in condensate water. Under the same the PH value, the acidity of carbon dioxide solution is higher than that of hydrochloric acid solution, causing a more intense corrosion attack to steel.

Carbon dioxide corrosion principle

CO2 + H2O → H2CO3

H2CO3 + Fe → FeCO3 + H2

3Fe + 4H2O → Fe3O4 + 4H2

Carbon dioxide corrosion form

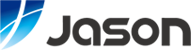

1) Wormhole attack corrosion

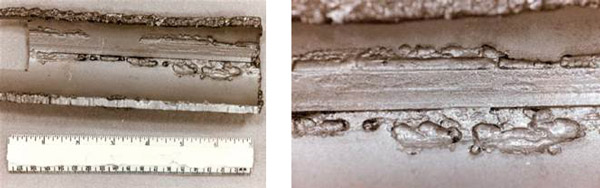

2) Ringworm attack corrosion

3) Heat affected zone corrosion

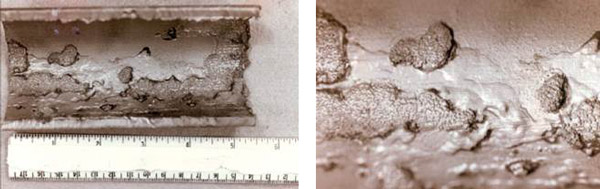

4) Mesa attack corrosion

5) Raindrop attack corrosion

6) Flow-enhanced corrosion

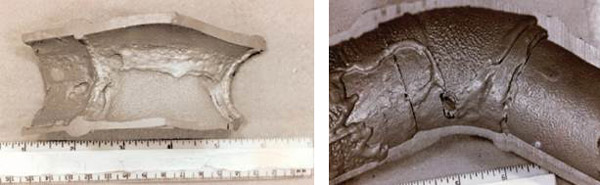

Carbon dioxide corrosion shape and appearance

· Even FeCO3 thin film

· Pit- from round to elliptic

· Round bottom

· Sharp edge

· Smooth side and bottom

· Hilly-and-valley-shape corrosion

Product of carbon dioxide corrosion

· Ferrous carbonate

· Ferroferric oxide

· Color-sepia, green, brown and black

Preventive Measures

· Choose corrosion-resistant steel, such as 18Cr and 2205 corrosion-resistant coiled tubing string manufactured by Jason Energy Technologies, Co., Ltd.

· Use corrosion inhibitor such as dichromate, phosphate and organic amine and so on.